HUMBLE BEGINNINGS.

Andrew McCain was a Canadian potato farmer in the early 1900s. Andrew saw an opportunity to expand beyond farming and selling potatoes locally and in 1909 created McCain Produce, a potato seed export company.

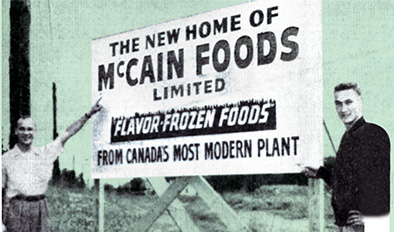

In 1957, Andrew’s sons, Wallace and Harrison McCain, along with their brothers Robert and Andrew, founded McCain Foods, opening the first production facility in their hometown of Florenceville, New Brunswick, Canada. Under Wallace and Harrison’s leadership, McCain Foods quickly established itself within the Canadian marketplace and then began a journey to become the world’s largest manufacturer of frozen French fries and potato specialties.

How it all began in Australia

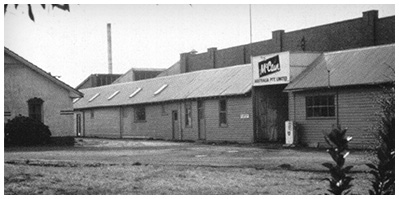

In 1968 McCain Australia was set up as a division of McCain Foods Limited, importing French fries from overseas.

Production starts in Daylesford, Victoria

With the fertile potato growing conditions in Victoria and frozen potato industry in infancy, it was obvious to McCain Australia to purchase potato farms and build a production facility. A small potato processing plant was built in Daylesford to manufacture frozen fries. Delicious and fresh, the fries were such a hit that we soon needed a new plant. And Ballarat, with its potato growing reputation, was where we built in 1974.

McCain Foods Makes Pizza!

As the Ballarat plant cooked up batch after batch of golden fries, the original Daylesford plant got a makeover to manufacture the latest product – pizzas. No one thought they’d be as popular as they were, and we were soon constructing another plant in Ballarat, just to produce pizza.

Tassie, here we come!

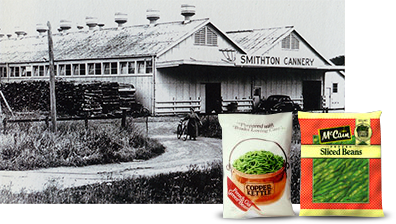

In 1984 we purchased the Copper Kettle Vegetable Processing Plant in Smithton, Tasmania. And we expanded our products from fries and pizzas to include farm-fresh vegetables. But there was more to come. In the same year, McCain Dinner Classics burst onto the market, with a range of low calorie, fresh dinners that the whole family could enjoy.

We grow a bit more

McCain gradually welcomed Chalet Foods, Gold Crest and Milani dinner products, into the family. This allowed us to offer a substantial variety of frozen dinners, including Low Calorie, Heart Foundation Approved, and our Healthy Choice range. In 1988, another potato processing plant was built in Smithton and Tasmania’s cool climate produced our best potatoes yet. In 1990 we purchased New Zealand’s Alpine Food Co – a vegetable processing company in 1992 we bought the Safries potato processing plant in South Australia.

New Zealand’s year

New Zealand now joined the ranks of McCain fans around the world. We built a potato processing plant in Timaru, right next door to the existing vegetable plant. With freshness as their number one priority, New Zealand now had McCain produce from their very own farmland.

Big changes

In the late ‘90s McCain began to blossom into the organization it is today. Multi-million dollar upgrades to the original Ballarat French fry plant saw epic leaps in production volumes. We tripled the size of our dinner manufacturing plant and installed a state of the art cold storage area in Ballarat.

Into the 21st Century

The first decade of the new century has seen a new dinner manufacturing plant and substantial upgrades to the vegetable plant in Hastings, NZ. Robotics was introduced into three of our plants, and we developed a range of delicious frozen fruits and sweet potato fries.

It’s all good

Since 1968, McCain has shown that if you produce the best quality food, you’ll soon become a trans-Tasman favourite. Especially when you maintain an unwavering pledge to ensure the highest quality in food safety, sanitation, ingredient quality and manufacturing integrity. From the farm to your table, McCain promises to deliver delicious, tasty and nutritious produce for years to come.

McCain Today.

McCain Foods Limited is a privately owned, multi-national leader in the frozen food industry, manufacturing quality products including French fries, appetizers, pizzas, vegetables, desserts, and prepared meals. We also own companies in complementary industries, such as agriculture and transportation. From just one factory in Canada’s Florenceville, New Brunswick, we’ve grown to become the world’s largest producer of frozen French fries. With the support of our owners, the McCain family, along with a dedicated team of professionals, a strong commitment to research and development, new product innovation and carefully chosen acquisitions, McCain continues to grow.

Globally, McCain Foods Limited has more than 21,000 employees and 52 production facilities working on six continents, generating annual sales over CDN $9 billion. For more on McCain Foods Limited, please visit: www.mccain.com

McCain Foods (Aust) Pty Ltd and McCain Foods (NZ) Limited are both wholly owned subsidiaries of McCain Foods Limited in Canada and are part of the global McCain group of companies. McCain Foods Australia & New Zealand has over 1,500 employees, 5 production sites, and sales presence in all major cities.

Our People.

People with passion are the key to our success – passion for continuous improvement, for teamwork, for learning and for delivering results. Our employees are our most valuable asset and we continually invest in our workforce to ensure it remains an industry leading team. We are committed to ensuring a safe and healthy working environment and conduct an annual Safety Day where all employees participate in demonstrations, presentations and workshops relating to health and safety both within the work and home environment. Our philosophy is that nothing we do is worth getting hurt for.

It’s a sign of a good company that people feel good – about themselves, about their job; and about their community. We’ve worked hard to create a friendly and diverse culture where everyone can do well. We want to attract committed, confident leaders at all levels, people who are lifelong learners valuing continuous improvement, driving performance and giving us great ideas to help keep us at the leading edge of our market.

SUSTAINABILITY.

People with passion are the key to our success – passion for continuous improvement, for teamwork, for learning and for delivering results. Our employees are our most valuable asset and we continually invest in our workforce to ensure it remains an industry leading team. We are committed to ensuring a safe and healthy working environment and conduct an annual Safety Day where all employees participate in demonstrations, presentations and workshops relating to health and safety both within the work and home environment. Our philosophy is that nothing we do is worth getting hurt for.

It’s a sign of a good company that people feel good – about themselves, about their job; and about their community. We’ve worked hard to create a friendly and diverse culture where everyone can do well. We want to attract committed, confident leaders at all levels, people who are lifelong learners valuing continuous improvement, driving performance and giving us great ideas to help keep us at the leading edge of our market.

EXPORT.

McCain Foods Limited has been an established exporter since the 1960s, initially supplying French fries around the globe to become one of today’s world’s largest manufacturers of frozen potato products for both retail and foodservice markets. With proven expertise in freezing and distribution of frozen food, McCain Foods ANZ has continued this drive, exporting potato and vegetable products from its facilities in Australia and New Zealand, strategically located in hearts of agricultural regions with reputations for prime growing conditions.

McCain Foods can assure a comprehensive food safety and quality management program led by its Global Quality Council, including strict manufacturing procedures, expert leadership, ongoing process innovation, use of quality ingredients and both internal and independent auditing. All McCain facilities receive and pass an annual third party audit against one of the internationally recognised GFSI approved standards and an unannounced Good Manufacturing Practices (GMPs) inspection conducted by AIB International.