Ballarat Energy Project

McCain’s Heat Recovery and Process Heat Electrification System

McCain is investing in a heat recovery and process heat electrification utilising Mechanical Vapour Recompression (MVR) system at our potato processing site in Ballarat, Victoria.

This is a significant project that will reduce our natural gas usage at our Ballarat potato plant by around 21 per cent. It will also lower our scope 1 emissions by approximately 5,900 tCO2e / year.

Project Description

The heat recovery and process heat electrification utilising Mechanical Vapour Recompression (MVR) will cost approximately $16.3 million, of which $7.38 million will be funded by the Australian Renewable Energy Agency.

McCain’s Ballarat site primarily processes potatoes into chips and hash browns. Incoming potatoes are washed and cleaned before having the skins removed. The raw potatoes are then cut into chips and processed in two different ways: one processes frozen uncooked chips and the second adds a batter and fries the chips before freezing and packaging. The chip length and quality are carefully controlled with off-cuts processed into hash browns. The process in energy and heat intensive with a 25 MW / 20 bar (g) gas fired boiler currently supplying the heat to the facility.

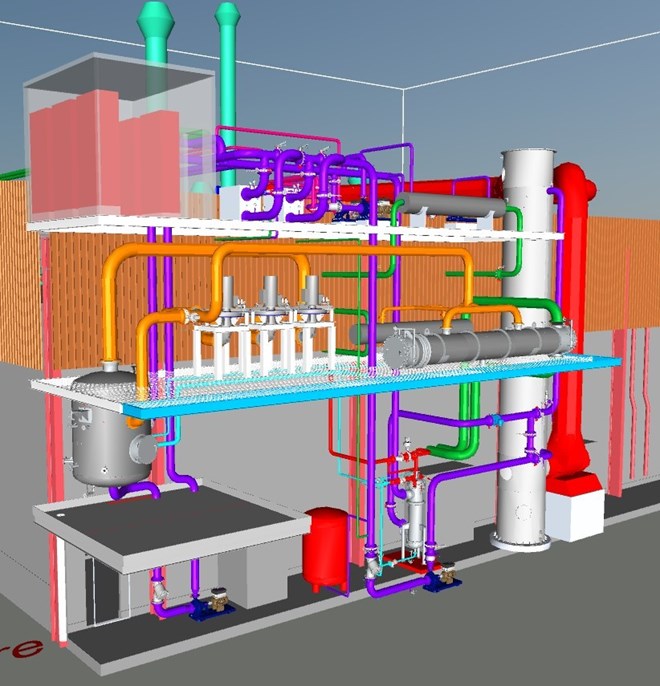

The heat recovery and process heat electrification project is comprised of two parts, the High-Pressure Condensate Recovery and The Fryer Heat Recovery Project.

McCain will implement upgrades to collect the high-pressure condensate from the fryer at 16 bar(g), and pump this at ~200°C directly back to the boiler, without any flash losses. High pressure condensate pumps with magnetic couplings (zero seal leaks) are proposed, which would remove steam losses and result in corresponding water savings in addition to energy savings. This is a reasonably novel idea when compared to the typical recovery of condensate to the boiler feed water tank with flash steam losses via flash vessel and -condensate tank itself. The implementation of this project will significantly reduce the flash steam losses.

McCain will also implement a Fryer Heat Recovery project. As chips are fried, moisture and heat is released from the potatoes into a humid exhaust air stream (~130 °C), which is scrubbed before being vented to atmosphere. There is approximately 6 MW of thermal energy available in this exhaust stream. McCain will recover some energy from the humid exhaust air of the fryer, the dew point of which is such that the majority of the heat is available at ~80 °C. It is proposed to generate an 80°C/55°C hot water loop, using the fryer exhaust air as the heat source. Heat sinks which can make use of this recovered energy include the dryer, blancher, preheaters, new hot water air pre-heaters, a new Sapp heater and a new hot water tank make-up heat exchanger. All of these users, with the exception of the Blancher, require up to 80°C hot water.

Schematic of the a Fryer Heat Recovery system for our Ballarat potato plant

The Blancher requires a higher temperature heat source of 90°C. This is where a 3 stage mechanical vapour recompression will be applied to upgrade the hot water source to 90°C steam which will then be supplied in two blancher heat exchangers (2 MW + 0.5 MW) respectively.

After some heat is already used, 75°C hot water stream will be flashed to 65°C, with flashed vapour collected and boosted via a 3 stage MVR installation to 90°C for use in the Blancher.

Knowledge Sharing Report

McCain will make publicly available knowledge sharing reports as the project progresses.

Contact Details

Industry and other stakeholders interested in our heat recovery and process heat electrification project should contact Avinash Sampath: [email protected]

Media inquiries should be directed to Dr Mark Roberts: [email protected]

ARENA Acknowledgement and Disclaimer

McCain Foods (Aust) Pty Ltd received funding from the Australian Renewable Energy Agency (ARENA) as part of ARENA's Industrial Transformation Stream Program.

The views expressed herein are not necessarily the views of the Australian Government, and the Australian Government does not accept responsibility for any information or advice contained herein.

ARENA Information

Further information about the project is available on the ARENA website: https://arena.gov.au/projects/mccain-heat-recovery-process-heat-electrification-utilising-mechanical-vapour-recompression-mvr/